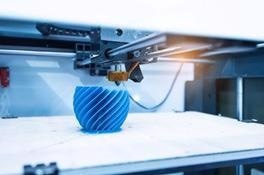

3D printing is an additive manufacturing process in which physical objects are created from a digital model file. The creation of a 3D printed object is achieved via a sequential layering of materials via the additive processes until the object is created.

Each of these layers can be seen as a thinly sliced cross-section of the object.

Image Credit: Superior Sensor Technology

3D printing is the complete opposite of subtractive manufacturing, which is cutting out/hollowing out a piece of plastic or metal with machinery such as a milling machine. Comparatively, 3D printing facilitates the production of complex geometries using less material than conventional manufacturing methods.

Most Common Types of 3D Printers

3D printing is a ‘catch-all’ term that refers to a number of different types of additive manufacturing technologies and processes. Today, there are at least ten different 3D printing manufacturing methods available.

While all of them can be used for quick prototyping and rapid manufacturing, advances in technology and declining costs have led to an uptake of some methods by hobbyists for home use and small businesses for light manufacturing.

These specific technologies are available in compact desktop versions and are used across an extensive range of applications, including jewelry, dentistry, confections, fashion (e.g., sneakers) and toys.

The two most frequently used types of 3D printers today are fused deposition modeling and stereolithography.

Fused Deposition Modeling (FDM)

FDM is also known as fused filament fabrication (FFF) and is the most commonly used 3D printing technology at the consumer level. FDM extrudes thermoplastic filaments via a heated nozzle to create an object, therefore melting the material and applying it layer by layer to construct the final product.

Stereolithography (SLA)

SLA was first invented in 1986. This method of 3D printing is still extremely popular, especially for professional applications. SLA 3D printers cure liquid resin into hardened plastic in a process known as photopolymerization. SLA is generally a better technology than FDM for manufacturing complex parts and those that must be airtight or watertight.

There are a number of other 3D printing technologies that are able to function using many different kinds of material besides plastic; these include ceramics, concrete, metals, paper and even edibles like chocolate.

These alternative technologies typically require more specialized and expensive 3D printing equipment. Whatever your business needs, there may be a particular device that serves as a better fit than FDM or SLA-based printers.

Figure 1. Desktop FDM 3D Printer. Image Credit: Superior Sensor Technology

Potential for Pressure Sensors in 3D Printers

It is relatively clear to see the value that differential pressure sensors can bring to 3D printers. For starters, attention can be drawn towards the nozzle where there is a demand for a consistent, predictable flow of material.

Otherwise, there is a significant risk of having inconsistent material placement when the object is being created. For example, it is important to see if the nozzle is being impeded by a filament or another object which affects the intended operation. Measuring the pressure of material flowing through the nozzle will clarify if this is the case or not.

It is also important to confirm that the ‘arm’ of the printer is applying enough pressure (but not too much) as each layer is ‘printed’ on top of the previous one. This ensures that the layers are well-bonded; otherwise, the object may end up warped or lopsided.

In this instance, a pressure sensor can be applied to measure the arm pressure against the object throughout the layering process.

Differential pressure sensors can also be applied to verify the structural soundness of the object as it is being fabricated. If values fall outside the pressure parameters, the sensor can instruct the printer to slow down the process so that existing layers have adequate time to ‘cool down’ and harden. This will ensure that the object meets the original design parameters.

Finally, making sure the object is structurally sound throughout fabrication will reduce the necessity of printing support structures for any parts of the 3D model that extend beyond the core base.

The pressure control coming from the differential pressure sensor allows the printer to change its speed until the necessary materials are adequately cured to the point of being able to support the structure’s overhang.

This reduces the amount of material needed to create the object and typically results in a quicker overall printing process since the need to ‘print’ the support structures is eliminated.

Superior Sensor’s NimbleSenseTM Architecture for 3D Printing

The NimbleSense architecture has an exceptionally low noise floor, which is perfect for the precise, low-pressure measurements that 3D printers demand to optimize accuracy and performance.

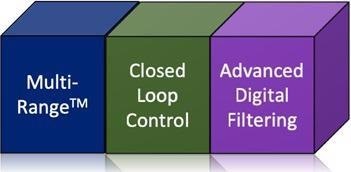

However, the advantages of NimbleSense extend beyond the low noise floor. Many of its application-specific building blocks offer extra value add for 3D printers.

Figure 2. NimbleSense Building Blocks that can Benefit 3D Printers. Image Credit: Superior Sensor Technology

Multi-Range TechnologyTM

Multi-Range technology allows one pressure sensor to operate at optimal performance levels over a number of different pressure ranges. Depending on the materials used for the object being ‘printed,’ the level of pressure required by the nozzle and the appropriate pressure needed for structural soundness will differ.

Multi-Range enables ‘on the fly’ pressure measurement adjustments to meet the requirements for many project regardless of materials used or pressure needed.

Closed Loop Control

An integrated closed loop control can enhance the speed, responsiveness and reliability of the 3D printer’s pressure sensing system.

The ability to do so reduces loop delays considerably and makes sure that readings are accurate by directly controlling any motors, valves and actuators that regulate the function of the nozzle, arms and other parts of the 3D printer.

Advanced Digital Filtering

3D printers are loud and can be affected by vibrations. Each of these factors can have a a major influence on the overall accuracy of pressure sensors.

Utilizing Superior Sensor Technology’s integrated state-of-the-art digital filtering technology, noise can be eliminated prior to reaching the sensor sub-system. Thus, the noise is canceled out before it becomes an error signal that can result in inaccurate readings.

Conclusion

The light manufacturing landscape is changing with the development of 3D printing technology.

As 3D printers become more commonly applied in a number of market applications, the capability to ensure precise material disposition and structural integrity will set the best performing products apart from the rest of the field.

Differential pressure sensors, especially those supplied by Superior Sensor, offer an easy, cost-effective solution.

To discover more about the NimbleSense architecture, or talk about a 3D printer project, visit Superior Sensor’s technology page or contact the company directly.

This information has been sourced, reviewed and adapted from materials provided by Superior Sensor Technology.

For more information on this source, please visit Superior Sensor Technology.