The Pressure Mapping Software Development Kit (SDK) is an Application Programming Interface (API) that enables users to achieve the highest performance with Tekscan’s pressure mapping software.

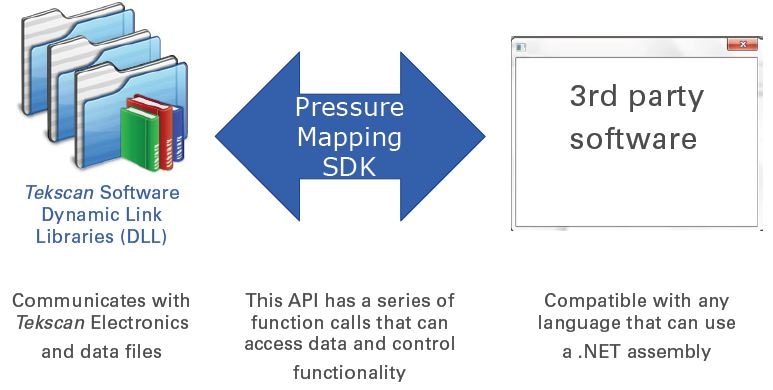

The developer can program an application that both controls and interfaces with Tekscan scanning electronics. Tekscan's Pressure Mapping SDK utilizes the Dynamic Link Libraries (DLL) which are responsible for data acquisition (DAQ) and analysis. DLLs are compatible with Windows XP onwards, and work with any language that can use .NET assemblies.

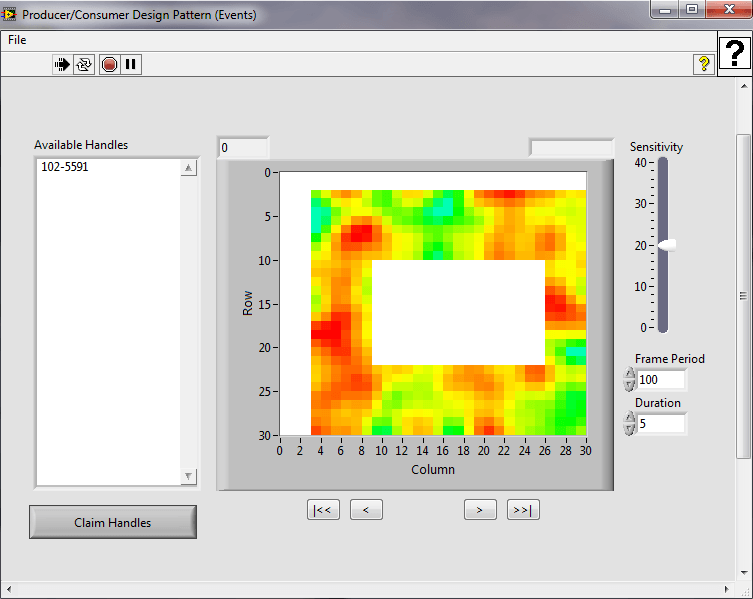

The Pressure Mapping SDK supports sample code for use in external applications, such as LabVIEW, VB, C#, and MATLAB. This has many benefits for the user, such as increasing the communication with Tekscan DAQ electronics to receive data, giving users the ability to control acquisition parameters when recording and saving data and the ability to read data from other saved work.

The Pressure Mapping Software Development Kit (SDK) is the perfect partner for users working in areas that require monitoring or repeated tests, such as OEM product integration, laboratory research and manufacturing (Quality Control, Test, Machine Setup).

Pressure Mapping SDK API

Key Features

The Pressure Mapping Software Development Kit (SDK) has key features that enable users to:

- Integrate pressure mapping with machine functionality

- Customize data output and display

- Open and read Tekscan data directly into preferred analysis software

- Customize UI (streamline procedures for operators

- Standardize measurement devices over multiple facilities

Pressure Sensor Output in LabVIEW

Benefits

Some of the benefits of the SDK include:

- Produce automated acquisition and analysis specific to application

- High quality standards, with quick, precise measurement and machine setup

- Faultless compatibility with a pressure mapping sensor

- Improved productivity with easy to understand UI customized for repeated processes

- Decreased downtime with early fault identification with live analysis

- Analyze data without having to save multiple file formats