InnovationLab, the expert in printed electronics "from lab to fab", today announced that it has been working with Trelleborg Sealing Solutions to integrate its printed sensors into an innovative logistics application. Trelleborg’s IntelliStok® inventory management system eliminates the need for the manual scanning of items, thereby saving time, increasing efficiency and reducing costs.

Image Credit: Trelleborg Sealing Solutions

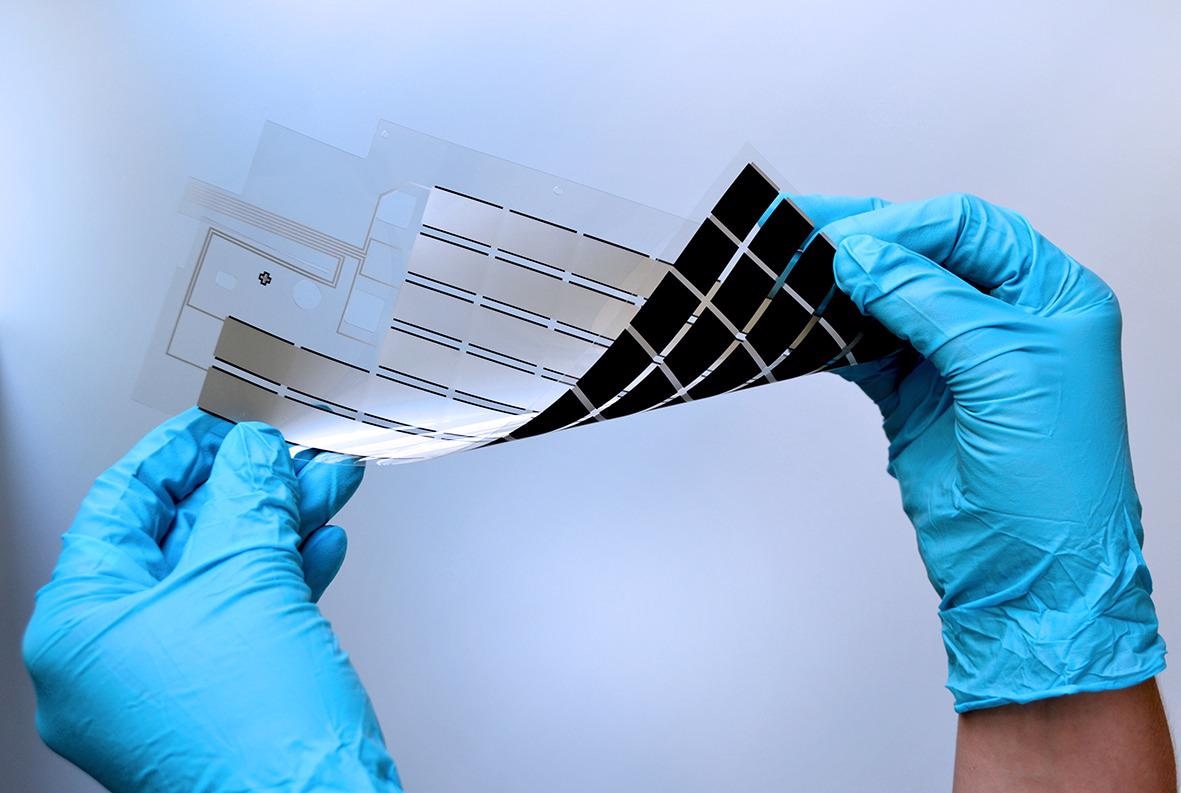

IntelliStok® works seamlessly with existing Kanban-based systems to provide real-time inventory tracking of the company’s sealing products. The system uses printed pressure sensor matrices from InnovationLab, which are placed inside existing storage bins at a warehouse. These sensors weigh the products in each bin and wirelessly send this data to the cloud.

"This was a challenging application. As our seals can weigh less than 1 g, we needed a sensitive, cost-effective system that could reliably provide accurate information," said Domenico Tucci, IoT Solution Architect at Trelleborg Sealing Solutions. "InnovationLab worked closely with us to develop a solution that exceeded our expectations and then manufactured the sensor matrices for us."

"We provide tailored solutions for our customers' challenges, from the initial concept to the industrial production of the final product," said Luat Nguyen, Managing Director at InnovationLab. "Our expertise is based on an indepth understanding of materials, processes and printing technologies – for Trelleborg, we researched and analysed possible solutions, and then designed and manufactured the optimal sensor matrix that met their specific needs."

Trelleborg set multiple requirements for the sensor matrix material such as low cost and sufficient durability to prevent deformation or creasing during use. InnovationLab undertook detailed research and testing of various materials, until it found a material that perfectly met all the criteria.

Trelleborg offers IntelliStok® as a service to its customers – triggering orders automatically for the replenishment of stock, directly in Trelleborg’s systems. The customer receives an email informing them of the order and the stock arrives shortly thereafter.

For Trelleborg’s customers, there are five standard-size sensor units available, which fit most bin types. The sensor matrices are integrated into a module that incorporates a microcontroller (MCU), a Wi-Fi chip for wireless connectivity and a 3.6 V lithium battery.