Interview conducted by Mychealla RiceMay 10 2017

Interview conducted by Mychealla RiceMay 10 2017

Nicolas Ho, Product Manager from ABB talks to AZoM about the reliable and convenient LLT100 Laser Level measurement sensor which is designed specifically for harsh environments and industrial applications.

Please tell us about the company and the work you do?

ABB's Measurement & Analytics business unit is among the world's leading manufacturers and suppliers of instrumentation and analyzers. ABB operates in more than 100 countries with about 132,000 employees.

ABB is a recognized manufacturer of Level Measurement Products, including state-of-the-art level instrumentation for liquids and bulk solids detection. Our products have demonstrated versatility in numerous applications, affording our customers a variety of practical and innovative solutions for their installation needs.

The ABB family of non-contact laser level products (LM80, LM200, and LLT100) provides solutions for accurate measurement in a wide variety of industries: oil & gas, chemicals, mining, power, food & beverages, and water & waste water.

I am the Product Manager for Laser level and volume measurement products at ABB. My work consists in making sure our clients have the best product we can offer. I manage the product roadmap, its marketing, training of our sales force and service groups, and the deployment of our products worldwide.

Why did ABB decide to introduce a new Laser measurement product? Was there a gap in the market?

ABB was a proponent of using laser technology for industrial measurements for many years. ABB offered the LM80 and LM200 which were popular to measure the level of bulk materials.

They were also used for measuring some liquids, like turbid liquids or colored liquids. Seeing the many advantages of laser level measurement in the industrial market, ABB decided to develop a more recent product completely tailored for industrial applications. We then launched the new LLT100.

This new product is really a step forward in terms of industrial measurements. It has all the advantages of laser ranging, in addition to being powered from the loop, having HART communication, being approved for hazardous area (FM class 1 / division 1), and having an embedded display with touch-through-the-glass interface. Most importantly, it also can detect any liquid, even transparent liquids, which is most convenient.

Why is laser measurement popular?

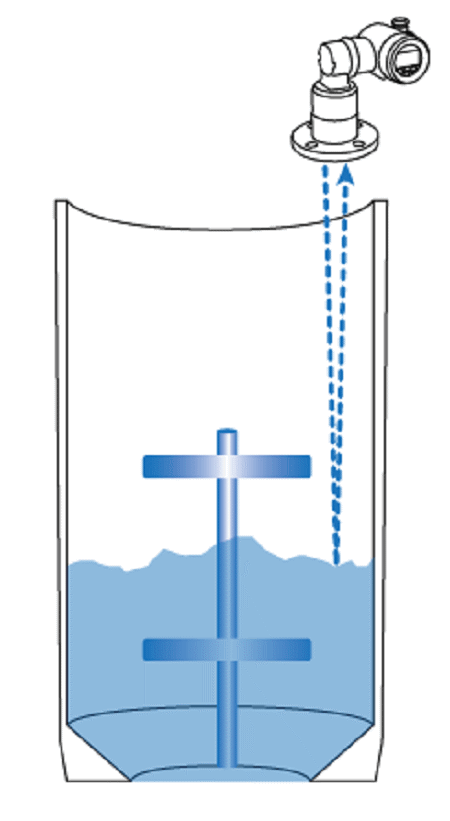

The laser level measurement is popular because of the simplicity of its use. The laser beam, being very narrow, doesn’t interfere with its surroundings and therefore is insensitive to its environment.

Typical technologies like open-path radar, for instance, have much larger beams and the user must map the echoes in the tank to make sure the instrument detects the right surface. If the environment changes, for instance due to build-up on the vessel walls, it might require a remapping of the echoes which causes time lost for the users.

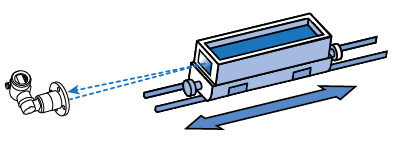

This entire concept doesn’t apply to laser level measurement as no echo mapping is required by the user. Also, since the laser beam is so narrow, it is possible to shoot it down narrow pipes (as small as 2 in.), through grids, or other kinds of constrained spaces. Finally, laser level measurement is not affected by the dielectric constant of materials. All materials will reflect enough light to be detected, so low-dielectric constant materials like plastics and oils are very easy to measure.

What applications can the LLT100 be used for?

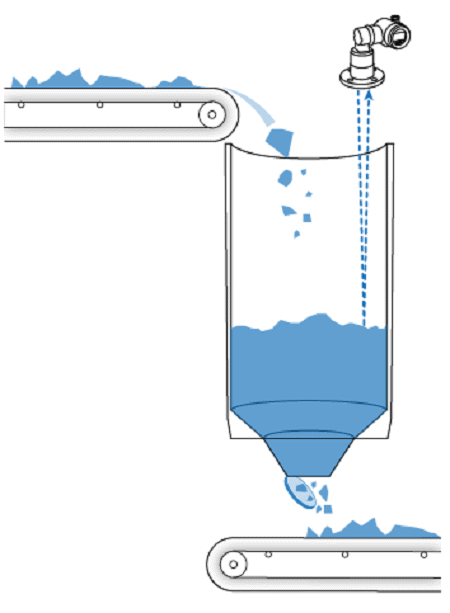

In many applications The LLT100 is used for inventory monitoring, so users can know how much material they have and therefore can manage their usage and procurement. LLT100 is also used for process control, where it provides automation of filling and emptying. In many application keeping the level to a given value will greatly improve the efficiency of the process. In these cases, the return of investment can be achieved in a matter of days after installing the LLT100.

Which types of industries will benefit from the Laser measurement instrument? Why?

The LLT100 benefits many industries. For the chemicals industry, its ability to measure liquids and low-dielectric constant materials such as plastics and polymers make it quite useful. In oil & gas, it is used for floating roof level measurement and tank level monitoring, where its reliability and simplicity make it very popular.

Laser level measurement has always been popular in the mining industry, to remotely measure the position of moving objects or to automate crushers and other filling operations. The ABB laser level measurement products are quite robust and made for these types of harsh environments, which is required in the mining world.

In water and waste water, it provides a good solution for long range level measurement and narrow spaces. Finally, laser level measurement is quite appropriate for the food & beverage industry, as non-contact measurement is a great advantage for hygienic applications.

Why is laser measurement not an established technology compared to well-known radar and ultrasonic non-contact sensors?

Ultrasonic and open-path radar transmitters have been on the market for a long time and are now well-established. In contrast, laser level measurement is much more recent. With the cost of lasers and photodetectors going down, laser technology has been used more and more for measuring distances and level in many applications. ABB is now introducing it in the industrial market, where it can solve many common problems.

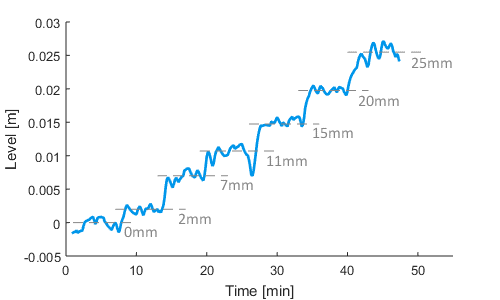

One of the main difference between LLT100 and other laser level sensors on the market is its ability to reliably measure clear liquids. It was designed for this purpose and tested on a variety of liquids, from opaque to transparent. Not only does it detect the liquid surfaces, it does so even when there is almost no liquid at the bottom of the tank. The image below shows the detection of a layer of 2 mm of liquids at the bottom of a stainless steel tank.

Level variations are due to waves and liquid filling. The LLT100 simplifies level measurement and allow non-contact measurement in applications that were not possible up to now.

Is laser level measurement easier to use compared to other products on the market? How?

Yes absolutely the laser level measurement is easier to use compare to many other technologies. Using a pulsed laser for performing time of flight measurement, the LLT100 provides accurate distance measurements while being powered from the 4 to 20 mA loop. Laser beams move through space with very little divergence, meaning they remain tightly focused even at long distances.

Since the laser beam doesn’t interact with the surrounding environment, there is no need to cancel false echoes: only the liquid or solid surface is detected.

Commissioning is thus simpler. Also, changes in the environment do not require changes in sensor parameters. For instance, material accumulation on the side of a vessel will change over time, requiring a remapping of false echoes. The same would happen if the sensor is moved. This will never be required with laser level measurement. Therefore it leads to superior reliability and more up time during use.

Laser beams also bounce back from surfaces very differently from ultrasonic or radar waves, which can be advantageous in several applications. Plastics, polymers, and low density materials are easily detected by laser sensors, as opposed to radar sensors. Also, there is no limitation on the angle of incidence for measuring solids with lasers, which simplifies installation.

Can the LLT100 be used in explosive atmospheres? How?

Yes absolutely. The LLT100 can be used in an explosive atmosphere because it is certified for use in hazardous areas (gas or dust). Even the laser beam is certified safe, since LLT100 has the OP IS approval which is the equivalent to intrinsic safety for lasers. It means the laser power is so low it can’t ignite a flammable gas.

LLT100 laser level measurement introduction

Where can the reader go to find out more?

The ABB website is a very good source on information about the LLT100 as well as all other laser level instruments at: www.abb.com/laserlevel.

To read more about the LLT100 click here:

About Nicolas Ho

Nicolas Ho is Product Manager for laser level and volume measurement at ABB. He is in charge of deploying laser measurement products worldwide.

Before he took this position, he was working at ABB as a system engineer where he focused on ABB’s space projects.![]()

His previous positions were in R&D for government entities and private industry.

Disclaimer: The views expressed here are those of the interviewee and do not necessarily represent the views of AZoM.com Limited (T/A) AZoNetwork, the owner and operator of this website. This disclaimer forms part of the Terms and Conditions of use of this website.