The VEGAFLEX 86 level sensor measures all liquids under extreme pressure and temperature conditions. Even in applications with buildup, condensation and foam generation, the sensor gives reliable and precise measured values.

In saturated steam applications, a special reference probe ensures a density-independent measurement. The VEGAFLEX 86 gives a cost-effective level and interface measurement for your given application.

Product Benefits

- Guided adjustment provides users with a simple, time-saving and reliable setup

- Probes can be shortened to offer simple standardization and high flexibility during the planning process

- Comprehensive diagnostic possibilities allow for maintenance-free operation and therefore a high plant availability

Level and Interface Measurement Performed at High Pressure and Temperature

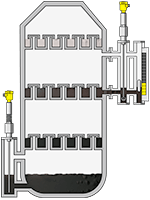

The VEGAFLEX 86 is a robust guided radar sensor which measures the level and interface of liquids at high process temperatures and pressures in tanks of all types.

The VEGAFLEX 86 operates independently of media properties such as density or dielectric constant in widely different vessels, bypasses or boilers.

The robust mechanical design and second seal (second line of defense) protect the sensor while it carries out demanding measurement tasks in the chemical, energy, petrochemical and oil/gas sectors. For example:

- Level and interface measurement in distillation columns

- Level measurement in gas tanks (LPG)

- Level measurement in steam boilers