With the VEGAPULS 6X, users get a sensor that can tackle any application, regardless of whether the medium to be quantified is liquid, hot, solid, cold, corrosive, or dangerous.

Users need not choose the right instrument from a multitude of various options. Instead, they specify the operational parameters and process conditions, and VEGA will put together a custom-made level measuring instrument suited to those needs.

Video Credit: VEGA Grieshaber KG

Simple, Simpler, The 6X®

The Exact Parameters Users Need for Their Application

Users simply need to provide VEGA with their desired parameters via the new configurator or at their personal consultation, and VEGA will choose the correct instrument version for their process.

From then on, it takes just a few days for their ideal radar level sensor to be manufactured, tested, and shipped.

As all settings in VEGAPULS 6X can be preconfigured to the user's application in advance, it can be used from the get-go. The display and adjustment module is clear, concise, and easy to comprehend. The instrument has Bluetooth for wireless adjustment with the VEGA Tools App.

Video Credit: VEGA Grieshaber KG

Born Where Values are Valued

Technology is Only as Good as the People Who Make It

That is why the new VEGAPULS 6X is a collaborative effort among 2,100 beneficial employees, six decades of valued measurement experience, and every value that is vital to VEGA.

Video Credit: VEGA Grieshaber KG

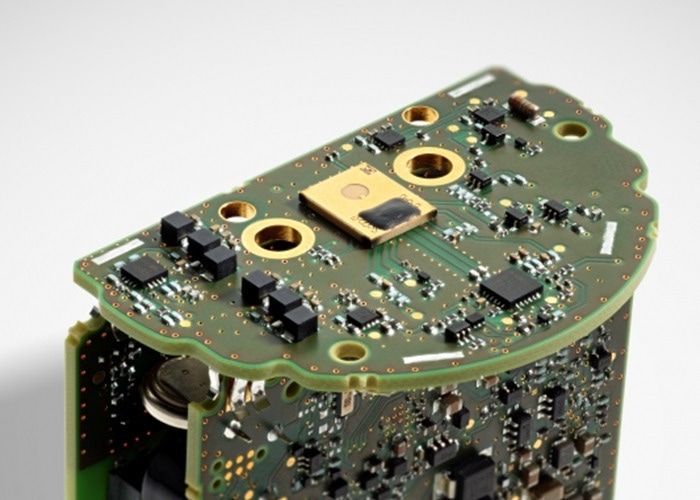

How to Find the Best Chip? Invent it

The radar chip within VEGAPULS 6X integrates the experience gained from three decades of radar-level measurement engineering.

Image Credit: VEGA Grieshaber KG

The Heart of the Sensor

If VEGA had to make a list of the most important innovations in its radar level sensor VEGAPULS 6X, its radar chip would be number one. The pulsating technology is at the heart of the sensor, which fulfills user expectations in terms of reliability and precision.

This is primarily the result of its potential to self-diagnose at the time of operation, which allows it to continually and smoothly track the precision and sensor performance.

Three Intrinsic Values: Accuracy, Reliability, and Ease of Use

At first glance, users are admittedly unable to tell what is inside the new VEGAPULS 6X radar sensor: A high-precision level instrument that does not care if they are bulk solids or measuring liquids.

The new radar level sensor VEGAPULS 6X integrates the best of the earlier 80 GHz, 26 GHz, and 6 GHz sensors, like VEGAPULS 64 and VEGAPULS 69, in a single device.

Video Credit: VEGA Grieshaber KG

Absolutely Precise and Secure

IT Security Standard IEC 62443-4-2

When it comes to increasing digitalization in industry, efficient protection against cyber attacks is essential. That is why the company has added in the new IT security standard IEC 62443-4-2 into VEGAPULS 6X.

It also means that the sensor is able to comply with even the highest cyber-security standards found in the process industry.

Image Credit: VEGA Grieshaber KG

Safety and Reliability Under all Process Conditions

Regardless of whether VEGAPULS 6X is functioning under high temperatures or high pressure, it always provides accurate measuring outcomes in applications of hot steam, dust, or extreme noise.

This is a result of its robust construction — using high-quality materials and encapsulated electronics to safeguard against external influences — and passing strict quality assessments that every sensor experiences.

Image Credit: VEGA Grieshaber KG

Risk Minimization According to SIL (IEC 61511)

Having been fitted with SIL 2/3, VEGAPULS 6X fulfills the exact and internationally standardized safety needs that safeguard health, the environment, and products during process operations. It helps obtain outstanding performance figures.

This sensor helps decrease safety risks and safeguards the system in the long term.

Image Credit: VEGA Grieshaber KG

Inner Values (Technical Data)

Process temperature: -196 to + 450 °C

Process pressure: -1 to +160 Bar

Measuring range: 120 M

Measurement accuracy: ±1 MM

How Does Level Measurement with Radar Work?

The Levels of all Media in Focus

VEGAPULS 6X concentrates the radar signal squarely on the medium. The reflected signals are examined and assessed to identify the level. As a result of its wide dynamic range, VEGAPULS 6X has the potential to detect even the smallest signals coming from media with poor reflective properties. Hence, the sensor is capable of reliably quantifying all media with high accuracy.

Video Credit: VEGA Grieshaber KG

Optimal Performance Thanks to Non-Contact Measurement

VEGAPULS 6X provides an extensive range of antenna systems — customized to users’ applications. The antennas fulfill the highest needs concerning hygiene and reliability.

In addition, the software algorithms of the sensor suppress interference caused by buildup on the antenna system or tank internals.

Thus, even foam, high mounting sockets, and small process fittings are no issue. The sensor is also able to quantify through plastic container walls.

Video Credit: VEGA Grieshaber KG

VEGAPULS 6X, Cyber Security and myVega

How do Sensors Contribute to Cyber Security?

As a result of the increasing trend toward digitalization in industry, effective protection against cyberattacks is considered to be an extremely important topic. Modern production facilities are becoming highly interconnected and utilize digital status retrieval on all devices and systems. This makes them vulnerable in a new form.

To help fulfill the highest cyber security standards presently implemented in the process industry, the VEGAPULS 6X radar level sensor has been developed per the latest IT security standard IEC 62443-4-2.

During a walk-through of the VEGA IT department, Jurgen and Stefan describe what has to be examined from the development stage for a secure sensor to be created.

Video Credit: VEGA Grieshaber KG

What Functions Does the Digital Customer Portal myVEGA Offer?

As a personal information platform, users can access several online functions concerning VEGA products. The company is constantly working on extending digital services so that users can access as much data as possible online and do tasks themselves. Nonetheless, the individuals' contact person is always at hand in myVEGA if help is required.

- Configurator for the complete VEGA product range

- Information on prices and delivery times

- 2D or 3D drawings for the user's configured instrument

- An overview of all order transactions

- Order directly online

- Instrument configurations can be saved

Video Credit: VEGA Grieshaber KG

VEGAPULS 6X: One Radar Sensor for All Applications

VEGA is proud to introduce the radar sensor that does not distinguish between bulk solids and liquids. VEGAPULS 6X is a sensor for all applications, irrespective of whether the measured medium is hot or cold, liquid or solid, or corrosive. VEGAPULS 6X integrates three core values:

- Precision,

- Security

- The feel-good factor

Video Credit: VEGA Grieshaber KG