Eddy current displacement sensors belong to the group of inductive displacement sensors and are ideal for industrial applications. In contrast to conventional inductive sensors, the measuring principle of eddy current sensors enables measurements on non-ferromagnetic materials (e.g. aluminium) as well as on ferromagnetic materials (e.g. steel). Micro-Epsilon's eddyNCDT family offers extremely precise non-contact and wear-free measurements of displacement, distance, position, oscillation, vibration and thickness. They are ideally suited for monitoring machinery and equipment as they can make measurements in harsh industrial environments, even where pressure, dirt, or temperature fluctuations occur.

Advantages over conventional inductive sensors

• High frequency response for dynamic measurements

• High resolution in the submicron range

• High linearity and temperature stability

• Measurement on ferromagnetic and non-ferromagnetic targets

• Non-contact measurement of displacement, distance and position on ferro- and non-ferromagnetic materials

• For harsh industrial environments: dirt, pressure, temperature

• High linearity, resolution and temperature stability

• Temperature range -40°C to 200°C and higher

• Resistant to oil, dust & dirt

Applications and Usage of Inductive Sensors Founded on the Eddy-Current Sensor Principle

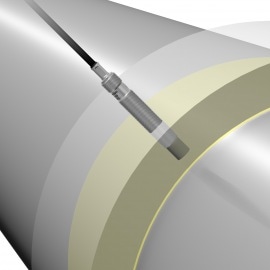

The high-frequency response of eddy current sensors allows metrological detection of distance values even in rapid processes, such as crankshafts and machine lathes, and IP67 protection guarantees they can be used in challenging industrial settings where humidity or dirt will not impact the measurement result. A typical example is checking the lubricating gap in a combustion engine.

Inductive Sensors (Based on Eddy-Current Principle) are Suitable for Machine Integration

Especially in areas with challenging environmental settings, inductive sensors from Micro-Epsilon (based on eddy-current) validate themselves. They are characterized by high measuring accuracy, simple operation, and a superior price-performance ratio. This renders the non-contact inductive sensors suitable for series production and OEM integration.

Measurement of oil film thickness

Custom Inductive Sensors for Automation and OEMs

Application examples are mostly found where the basic versions of the inductive sensors and the controller are performing at their maximum. For these special operations, the inductive sensors can be altered accordingly. Changes demanded include, for instance, adaptable designs, individual cable lengths, various mounting options, target calibration, adaptable measuring ranges, or sensors with an in-built controller.

What is an Inductive Displacement Sensor?

Inductive displacement sensors not only sense the presence of a target (similar to inductive proximity switches) but precisely compute the distance from a target. Thus, eddy current based inductive displacement sensors deliver higher frequency response, better linearity, enhanced temperature stability and larger measuring ranges than inductive sensors with ferrite core.