Micro-Epsilon’s non-contact displacement sensors and systems facilitate high precision thickness measurements in a wide range of applications. Here, a difference is made between a one-sided and a two-sided thickness measurement. In the case of one-sided thickness measurements, the sensor establishes the target thickness from one side only. Two-sided thickness measurements are performed using at least one pair of sensors placed opposite each other in one axis. The most crucial measurement operations are mentioned below with suitable measurement technology.

One-sided Thickness Measurement of Transparent Materials Using Confocal Sensors

The confocal measuring principle allows one-sided thickness measurement of transparent materials such as display glass. This means that just one sensor is needed for one measuring point. Micro-Epsilon’s confocal chromatic sensors assess up to six peaks during the measurement, enabling them to monitor separate layers and gaps.

The confocal measuring principle allows one-sided thickness measurement of transparent materials such as display glass. This means that just one sensor is needed for one measuring point. Micro-Epsilon’s confocal chromatic sensors assess up to six peaks during the measurement, enabling them to monitor separate layers and gaps.

One-sided Thickness Measurement of Plastics and Applied Adhesives

The combiSENSOR integrates a capacitive displacement sensor and an eddy current sensor in a single housing and is used for variance thickness measurements of adhesive and plastic. The sensor usually requires a metallic counter electrode (typically a transport roller), which is detected as a reference distance. The in-built capacitive sensor records the distance from the non-conductive plastic or adhesive layer. The controller calculates the thickness of both sensor signals with excellent accuracy. With the combiSENSOR even extremely thin materials can be measured.

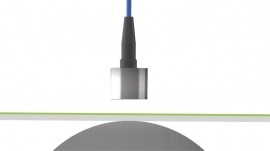

Two-sided Thickness Measurements Using Capacitive Displacement Sensors

To carry out very accurate thickness measurements of electrically conductive materials, capacitive displacement sensors can be employed, which are placed opposite to one another. The intelligent controller processes and computes the sensor signals so that the thickness measurements can be output straightaway. With this technique, the thickness of extremely thin targets, for instance, silicon wafers can be measured at high accuracy.

To carry out very accurate thickness measurements of electrically conductive materials, capacitive displacement sensors can be employed, which are placed opposite to one another. The intelligent controller processes and computes the sensor signals so that the thickness measurements can be output straightaway. With this technique, the thickness of extremely thin targets, for instance, silicon wafers can be measured at high accuracy.

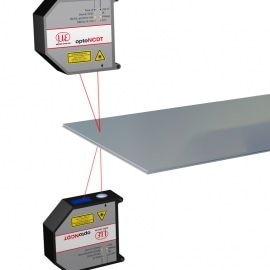

Two-sided Thickness Measurements Using Laser Sensors

Laser displacement sensors placed on two sides detect the thickness of various objects according to the differential thickness technique. The measurement can be performed on a range of targets, for example, plastics, wood, metals, and coated glass. The sensors have to be synchronized and exactly aligned to acquire accurate readings. Based on the measuring range, the sensors can be aligned at a great distance from each other. The thicknessSENSOR is a turnkey sensor system that is designed for thickness measurements.

Laser displacement sensors placed on two sides detect the thickness of various objects according to the differential thickness technique. The measurement can be performed on a range of targets, for example, plastics, wood, metals, and coated glass. The sensors have to be synchronized and exactly aligned to acquire accurate readings. Based on the measuring range, the sensors can be aligned at a great distance from each other. The thicknessSENSOR is a turnkey sensor system that is designed for thickness measurements.

Systems for Thickness Measurements of Black Rubber Webs

To handle thickness and profile measurements of tire components and technical rubber, Micro-Epsilon provides industry-specific measuring systems that can be combined into the production process. These turnkey systems are provided with application-specific sensors and equipped with widespread interface and software packages.

Systems for Thickness Measurements of Plastics

In order to perform the thickness measurements of film and thin plastics, Micro-Epsilon delivers turnkey measuring systems that are integrated straightaway into the production line. The systems are built to carry out inline thickness measurements of plastic film from 10 μm and upwards. Based on the location of use, the measuring systems are fitted with application-specific sensors, software packages, and interfaces.

Systems for Thickness Measurements of Metal Strip and Plate

To handle the thickness monitoring of metal strip and metal plate, measuring systems with application-specific sensors are provided. Based on the model, the systems can be used in hot or cold rolling mills. For traversing bandwidth monitoring, O-frame systems are employed, whereas C-frame systems are used to measure separate tracks. The systems work independently of surface and alloy properties and so can be used across the whole metal processing sector.

To handle the thickness monitoring of metal strip and metal plate, measuring systems with application-specific sensors are provided. Based on the model, the systems can be used in hot or cold rolling mills. For traversing bandwidth monitoring, O-frame systems are employed, whereas C-frame systems are used to measure separate tracks. The systems work independently of surface and alloy properties and so can be used across the whole metal processing sector.

Sensors and Systems for Precise Thickness Measurements

One-sided thickness measurement of plastics and applied adhesives

Two-sided thickness measurements using capacitive displacement sensors

Two-sided thickness measurements using laser sensors

Systems for thickness measurements of black rubber webs

Systems for thickness measurements of plastics

Systems for thickness measurements of metal strip and plate