The optoNCDT 1900 is the most recent model of laser sensors from Micro-Epsilon that can be used for measuring dynamic displacement, position, and distance. These novel laser sensors provide an exclusive blend of compact design, accuracy, and high speed.

The built-in high-performance controller allows highly accurate and rapid processing and output of measurement values. Micro-Epsilon’s optoNCDT 1900 laser triangulation sensor fulfills the requirement of maximum precision with the most advanced technology.

The laser sensor performs measurement tasks in the fields of 3D printing, car manufacturing, and automation, as well as in coordinate measuring machines.

Highest Stability Ensured by Intelligent Signal Optimization

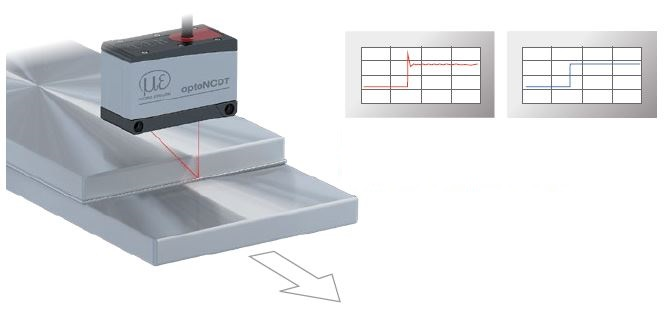

For the first time, the optoNCDT 1900 laser sensor incorporates a two-step measurement value averaging feature for optimizing the signal. This feature ensures a smooth signal at steps and edges. Specifically, in the case of high-speed measurements of parts that move, measurement averaging allows an accurate signal course.

The two-step measurement value averaging enables smooth signal courses when measuring edges (right). Otherwise, interfering signals occur (left).

Advanced Surface Compensation—Intelligent Exposure Control for Challenging Surfaces

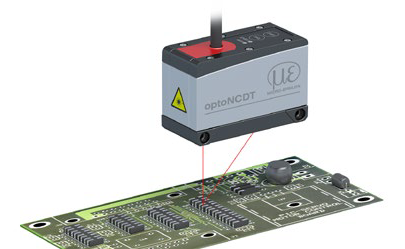

The optoNCDT 1900 laser sensor is provided with a smart surface control feature. New algorithms facilitate stable measurements even on challenging surfaces that present varying reflections.

The novel laser sensor is highly resistant to ambient light. It is suitable for use even in highly illuminated environments. New algorithms help compensate for ambient light with an illuminance of up to 50,000 lux.

Advanced Surface Compensation: With rapidly changing surfaces, the exposure control enables reliable measurement results.

New Mounting System for Accuracy of Fit

Since the laser sensor is mounted with the help of fitting sleeves, it gets automatically aligned in the accurate position. This facilitates not only the easy replacement of the sensor but also higher precision while solving measurement tasks.

The sensor occupies a space of only 70 mm x 31 mm x 45 mm. Specifically, thickness measurements performed using two optoNCDT 1900 sensors demonstrate the advantages of this mounting system, since it is possible to accurately align the light points.

Patented installation: Easy mounting and high repeatability with the sensor replacement.

Key Features

- Built-in electronics ensure a compact size

- Adjustable measuring rate of up to 10 kHz

- Analog and digital outputs

- Measuring ranges (mm): 10, 25, or 50 mm

- Linearity from 2 µm

- Individual and predefined presets in web interface

- Advanced Surface Compensation enables fast adaption to varying surfaces