The thicknessGAUGE sensor systems from Micro-Epsilon enable accurate thickness measurements of strip materials, plates and sheets. Based on the measurement process, various models with different sensor technologies are available, which are known for unsurpassed price/performance ratio. The system includes an electromechanical drive and an automatic calibration unit.

Many models with different sensor types, measuring widths and measuring ranges enable inline thickness measurements on different materials and surfaces at an unmatched price/performance ratio.

The completely assembled system consists of a stable frame upon which two optical distance sensors are mounted. The sensors are capable of detecting the thickness of the measured objects as per the difference principle.

The sensors are ideally aligned and calibrated to each other during assembly. Furthermore, the thickness calibration at the factory guarantees increased accuracy.

The thicknessGAUGE system comes with laser triangulation sensors, laser profile scanners or confocal chromatic scanners. These add to the performance based on the type of material and precision needs.

Strips and plates are measured with maximum accuracy without contact. The system provides the highest application versatility as it offers the suitable measurement principle depending on needs, measuring thickness from 2 to 25 mm.

Automatic Calibration and Temperature Compensation

The thicknessGauge systems are loaded with in-situ calibration to compensate for the effects of temperature variations. A linear axis moves the thicknessGAUGE into the parking location.

The calibration cycles can be adjusted individually. For temperature compensation, in-situ calibration facilitates the accurate functioning of the system to be verified cyclically and at any time.

The New Class for Inline Thickness Measurements

A linear unit with the electromechanical drive allows for the thickness to be measured in traversing mode. On the other hand, it is possible to do fixed track measurements for centerline measurements (center thickness) or thickness measurements at the edges.

The compact system comprises a combined linear unit, including motor control, a compact bud junction box, an automatic calibration unit and a multi-touch PC with pre-installed software. A 24 V source provides the power supply for the whole system.

Powerful Analysis and Control Software

The thicknessGAUGE systems are loaded with a multi-touch capable software package. This enables analysis, presentation and archiving of monitored production data.

This software facilitates various modes, such as fixed track thickness measurement at any position, measurement of several longitudinal trends, measurement of thickness profile, an SPC package and automated verification of the capability of the measuring system.

The system also ensures simple and quick verification of the measuring system capability that can be individually adjusted.

100% Quality Control During Production

The thicknessGAUGE sensor systems find applications in plate production and strip processes for continuous thickness measurement at individual measuring points.

These systems have been engineered such that they are applicable as both initial equipment, and for retrofitting current facilities. The thicknessGAUGE sensor systems are provided by intelligent sensor technology and feature high precision, thereby finding use in different industries.

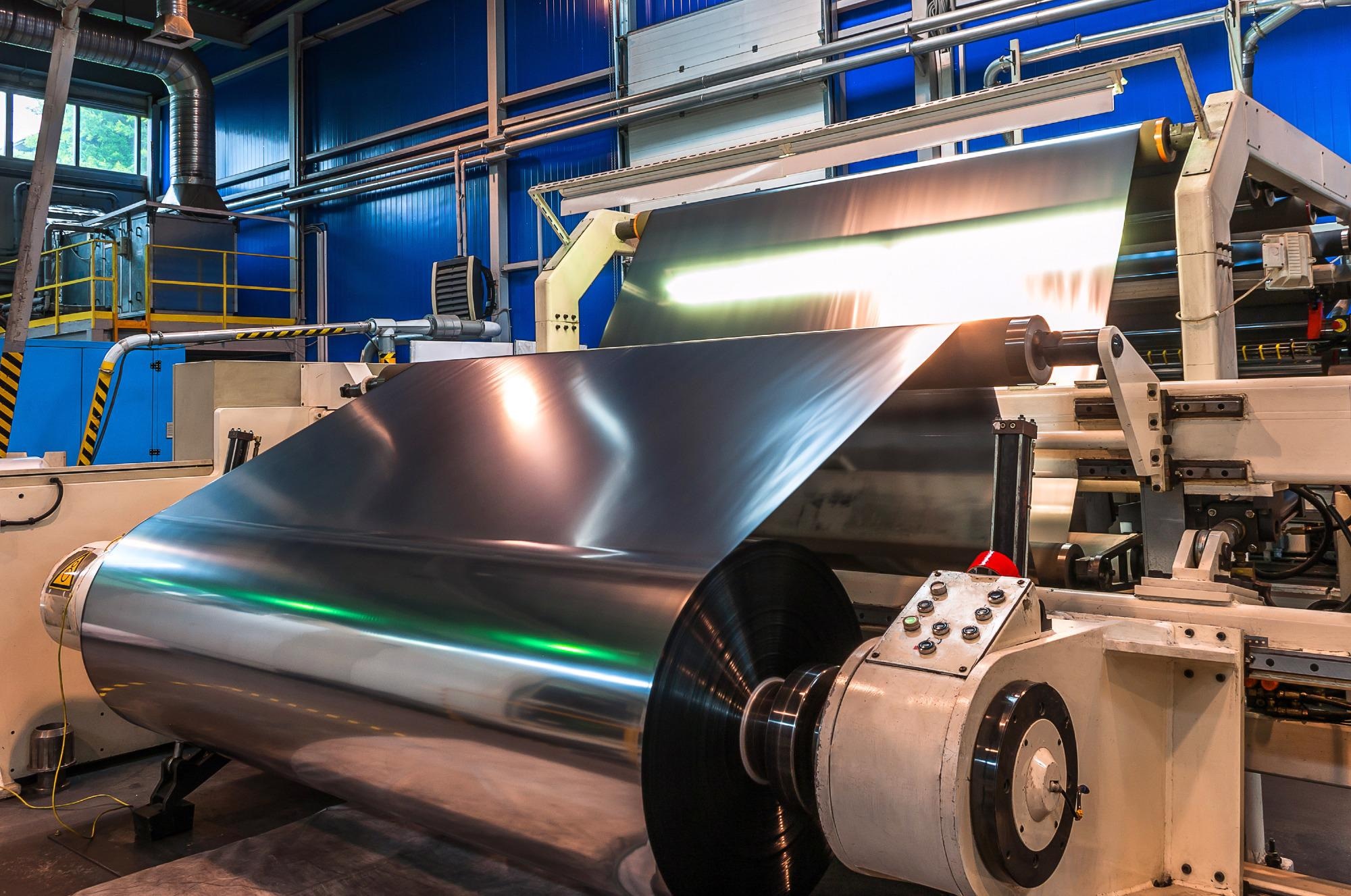

Metal production — Thickness measurement of metal film, metal strips and metal plates. Image Credit: Micro-Epsilon

Energy industry — Thickness measurement of fuel cells and battery film (coated and uncoated). Image Credit: Micro-Epsilon

Material engineering — Thickness measurement of film, plastic plates, woven materials, wood and ceramics. Image Credit: Micro-Epsilon