Kistler Instruments has added three new measuring ranges to its KiTorq torque measuring system.

The new ranges of 100, 200, and 5 000 Nm have been added to the existing ranges of 500, 1,000, 2,000 or 3,000 Nm measuring ranges. All ranges are available with an accuracy class of 0.05% of range. These additional ranges complete the portfolio for test benches for internal combustion engines, electric motors, transmissions and drive trains.

Rotors of different sizes can be combined with same ringless stator, which is particularly easy to install and allows different items to be tested without the complete reconstruction of the test stand. The ringless stator design speeds up the installation, protects against damage during assembly operations and facilitates visual observation during the test process.

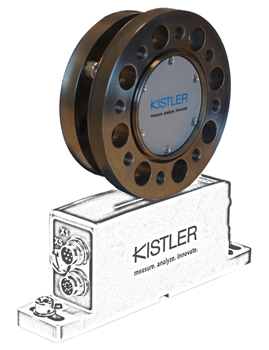

KiTorq torque measuring system.

KiTorq torque measuring system.

A single, intelligent stator can be used with any KiTorq rotor of the same speed rating and will automatically recognise the rotor measuring range. This minimises hardware investment as one stator may be used with rotors of differing ranges for different applications. Installation is simplified by the contactless, digital telemetry that does not require an antenna ring. The lack of an antenna ring has not reduced the precision of the sensor which has an excellent signal bandwidth of 10 kHz and accuracy of better than 0.05%. A speed measurement of 60 pulses per revolution is integrated in the standard system.

The stator is now available with Profibus, Profinet CANopen and Ethernet interfaces in addition to the analog / frequency, USB and RS-232 interfaces which allow analogue and digital signal outputs to be fully scalable. When needed, the rotor's original measuring range may be overridden to allow the full output signal to be available over a defined range. A second, freely selectable measuring range may also be defined at each output.

The solid measuring flange is extremely robust and has been tested to EN 60068-2-27 for mechanical shock, EN 60068-2-6 for triaxial vibration loading and EN 61326-1 for interference immunity. The KiTorq system is supplied as standard with SensorTool configuration and diagnostic software and calibration certificates. Several calibration options are available for the configurable output signals of the KiTorq system and when replacing an individual rotor or stator, the notional calibration values can be calculated to avoid the need to have the unit recalibrated by the manufacturer.

The KiTorq measuring flange is ideal for use in test rigs for electric motors, internal combustion engines, transmissions, pumps and compressors.

Kistler Group

Established in Winterthur (Switzerland) in 1957, the Kistler Group now has a worldwide presence with 25 group companies and 30 distributors ensuring prompt, local application support and short delivery times. With a staff of more than 1200, the Kistler Group is one of the world's leading providers of dynamic measuring instrumentation with a turnover of 235 million Swiss Francs (GBP 156M) in the 2011 financial year.

Kistler's core competence is the development, production and use of sensors for measuring pressure, force and acceleration. Kistler's know-how and electronic systems can be used to prepare measuring signals for use in analysing physical processes, controlling and optimising industrial processes, improving product quality in manufacturing and improving performance in sports and rehabilitation.

Heavy investment in research and development, 15% of staff worldwide are engaged in research and development, has generated a number of innovations using piezoelectric, piezoresistive and capacitive techniques to provide solutions to numerous force, pressure and acceleration measuring problems. These innovations include the world's first commercial quartz sensor, two-wire constant current technology to integrate sensors with microelectronic circuitry, high-temperature pressure sensors for use up to 400 Deg C and three-component force measuring sensors.