May 10 2016

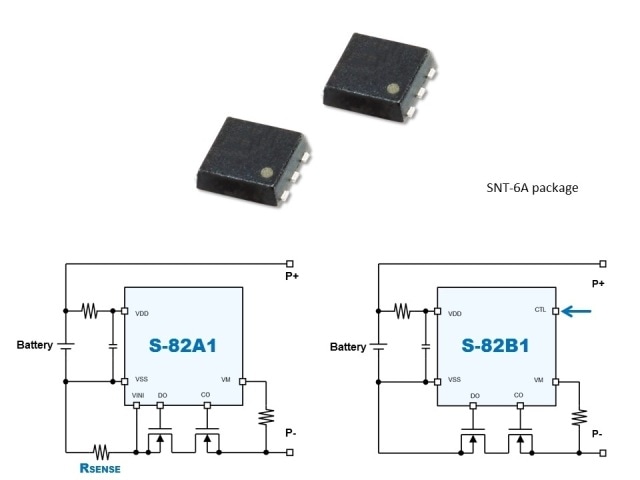

SII Semiconductor Corporation, a subsidiary of Seiko Instruments Inc., introduces two new 1-cell lithium-ion battery protection ICs. The S-82A1 Series incorporates a Sense Pin (VINI) which allows for the use of an external Sense resistor enabling highly accurate overcurrent condition detection. The S-82B1 Series includes a Control Pin (CTL) which allows the user to control charge and discharge externally through the control pin signal. Both series are suitable for all applications using 1-cell lithium-ion batteries including smartphones and wearable devices.

SII Semiconductor Corporation Introduces New 1-Cell Lithium-ion Battery Protection ICs with Temperature and Charge/Discharge Control Options (Graphic: Business Wire)

SII Semiconductor Corporation Introduces New 1-Cell Lithium-ion Battery Protection ICs with Temperature and Charge/Discharge Control Options (Graphic: Business Wire)

The S-82A1 Series with the use of an external sense resistor allows for high accuracy overcurrent detection over the operating temperature range and power supply voltage variation. A discharge and charge overcurrent detection voltage accuracy of ±3mV can be achieved with this series. This industry-leading accuracy allows for higher reliability and safety of lithium-ion battery packs.

As the capacity of the batteries increases and the charge current increases, the heat generated through charge is increasing and is a hot topic for design consideration. To minimize the heat in the current path, overcurrent detection resistors with low resistance value are needed. The S-82A1 Series can support overcurrent detection resistors with lower resistance values as the charge and discharge overcurrent detection voltage settings are selectable down to 10mV. This unique feature allows the S-82A1 Series to help in the reduction of heat generation in the protection circuit.

The new S-82B1 Series incorporate a charge-discharge control pin which allows control of the charge-discharge externally. By connecting a PTC thermistor to the control pin, for example, a temperature protection function to disable battery pack charge-discharge can be added at a user selectable set point. It is also possible to use the control pin to disable charge-discharge of the battery at the factory production site to reduce power consumptions to the lowest possible level before shipping the end product to the customer. This is possible even when the battery pack is connected, which allows for easy testing of the current consumption of the end product by simulating the removal of the battery pack.

Both the S-82A1 and S-82B1 Series are available in the super small SNT-6A package(1.6×1.8×0.5mm.)