From HypersenReviewed by Danielle Ellis, B.Sc.Nov 18 2022

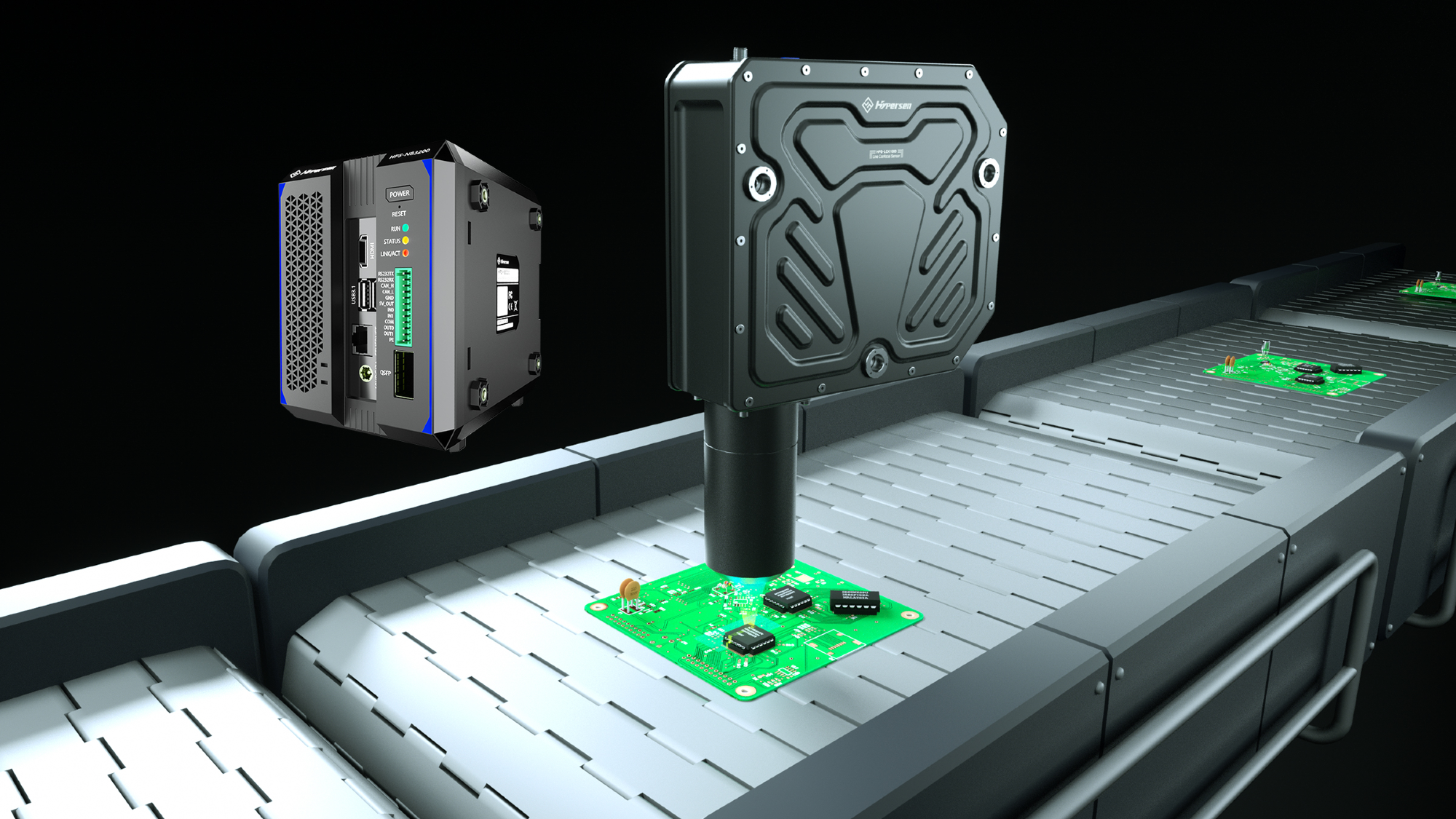

As a leader in chromatic confocal technology, Hypersen is pleased to release a Coaxial 3D Line Confocal Sensor (HPS-LCX1000) for the global measurement & inspection market. This sensor offers an effective and high-precision (0.1µm) 3D inspection solution to the measurement and defects detection problems in the fields of semiconductors, consumer electronics, new energy, metal, automobile, and aviation.

Compared to current line confocal sensors, HPS-LCX1000 excels in its lateral resolution (1.1µm) and coaxial structure. Coaxial design means the incident and reflected rays overlap. Therefore, it solves the shadowing problem when measuring targets with holes, steep slopes, and protruding components.

In addition, it has the following advantages:

- High adaptability to various materials, especially transparent and highly reflective ones, mirrored surfaces, and even liquid

- Robust capability to measure complex geometric shapes

- Max. surface slope on mirror: ±45°

- Generate 2D image and 3D point cloud data by one scan

- Axial precision: 0.1µm

- Point density: 2,048 points/profile

- High scan speed: up to 35,000 lines/sec.

Separated sensor head and controller design greatly reduces the measurement error caused by heat generation of the sensor. Besides that, a 40G optical fiber enables low-latency data transmission between the sensor head and the controller. What’s more, the controller is equipped with an 8-core 64-bit CPU, high-speed FPGA and an AI accelerator. With integrated high efficient AI algorithm, HPS-LCX1000 reaches a scanning speed of 35,000 lines/sec. and enables real-time 3D point cloud data output.

What HPS-LCX1000 can do:

- 3D topography and dimension measurement

- Surface defects detection

- Curved surface measurement

- Displacement and roughness measurement

- Gap and flush measurement

- Thickness measurement of multi-layer transparent materials

- Test engineers can find this sensor very helpful when conducting the following tasks:

- Wafer and PCB bumps 3D inspection

- Die defects detection

- IC chip pin 3D inspection

- Wire bonding defects detection

- Highly angled LED/OLED display profile measurement

- Smart watch components measurement

- Gluing effects inspection

- Automotive and aerospace components appearance inspection

Article Revisions

- Jan 28 2025 - Meta Title and Description has been updated to fall inline with Google recommendations